Holistic Innovation in Additive Manufacturing

July 23-24, 2025 | Waterloo, ON, Canada

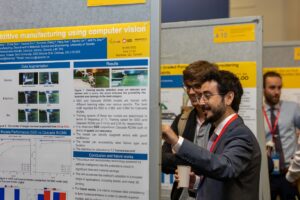

About the HI-AM Conference

HI-AM 2025

Location: Waterloo, ON, Canada

Venue: University of Waterloo - Engineering 7 (E7)

Dates: July 23-24, 2025

Important Dates

| Abstract Submission Opens | January 6, 2025 |

| Abstract Submission Deadline | March 7, 2025 |

| Abstract Acceptance Notice | April 1, 2025 |

| Manuscript Submission Opens | April 1, 2025 |

| Manuscript Deadline | July 10, 2025 |

| Registration Deadline (Presenting Authors) | June 2, 2025 |

| Registration Deadline | July 10, 2025 |

| Proceedings Published | November 2025 |

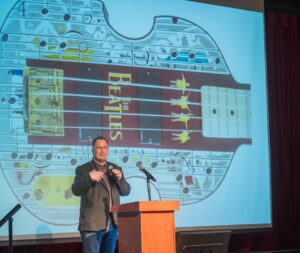

Keynote Speakers

Behrang Poorganji

Behrang Poorganji

Presentation Title

Abstract

Additive Manufacturing is rapidly transitioning from a prototyping tool to a robust industrial production technology. Yet, the qualification of new materials and processes remains one of the most significant challenges in wider adoption of metal AM since it is slow, complex, and expensive. In this talk, Nikon’s vision for AM, along with our current technologies, platforms, and strategies for accelerating qualification will be shared. We’ll present case studies of how an integrated, multi-scale approach is being applied to break through these barriers and enable faster AM adoption. By leveraging smart design-of-experiments, high-throughput testing, advanced material characterization, and in-process monitoring, we are streamlining the path from development to qualification. We'll also explore the role of non-destructive evaluation and Integrated Computational Materials Engineering (ICME) in reducing risk, compressing timelines, and lowering costs. This is more than process optimization—it’s a reimagining of the entire AM qualification pipeline. The result: a smarter, faster, and more scalable pathway to true industrial-grade manufacturing.

Biography

Dr. Behrang Poorganji is a seasoned professional with over 20 years of experience in advanced metallic materials processing and Metal Additive Manufacturing. He currently serves as a VP of Technology Nikon where he leads technological advancements in the metal additive manufacturing field. Behrang career trajectory includes diverse leadership and management roles across international borders, including Japan, Canada, and the USA. With a strong foundation in aerospace, power management, and automotive industries, he has demonstrated his adaptability and strategic acumen. Behrang has served as an influential advisor and consultant, contributing to the broader adoption of additive manufacturing solutions across global industries.

Ante Lausic

Ante Lausic

Presentation Title

Abstract

As other industries take off with AM adoption, the automotive segment has laboured behind. The tight margins and enormous volumes have prevented mass adoption of AM and this talk seeks to highlight those roadblocks. Success stories at General Motors present key technologies and applications to build off of for future mass market adoption. While working to compete with conventional manufacturing methods, AM has also shown an ability to complement the automotive manufacturing process including casting, assembly, and in limited scenarios, serial production. Examples will include the Cadillac CT4-V and CT5-V Blackwings, the Chevrolet Tahoe, and the Cadillac Celestiq ultra-luxury sedan.

Biography

Dr. Ante Lausic is the Lead Process Engineer for General Motors metal additive manufacturing work out of Warren, MI, USA where he works to industrialize PBF, DED, and MBJ for use in automotive production and manufacturing. He has spent 16 years in the AM field with the last 8 years focused on automotive and tooling applications. Dr. Lausic also supports the Canadian ISO delegation in developing standards for the AM industry.